The SR+ could become the new standard for small wearable devices

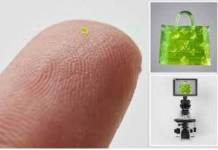

Corning Inc (NASDAQ: GLW) unveiled a new glass composite for wearable devices. The Gorilla Glass SR+ promises to deliver more damage resistance, optical clarity, and touch sensitivity, according to a press release from Friday, August 30th.

The company is known for manufacturing toughened glass designed to serve as a thin and light cover material. Some of the smartphones currently using this technology are the Google Nexus 6P and Samsung’s Galaxy Note 7. Now, Corning is making the transition to more challenging wearables.

The Gorilla Glass SR+ uses a combination of components from the previous Gorilla Glass 5 with more luxury materials such as sapphire. Last year, the company launched this kind of process with the name ‘Project Phire’ to add scratch resistance on its products.

What are the advantages of Gorilla Glass SR+?

Scott Foster, Director of Innovation Products for Corning Gorilla Glass, said the SR+ delivers superior cover properties currently unavailable in any other material.

During Lab tests, the Gorilla Glass SR+ demonstrated greater scratch resistance when compared to other luxury materials. It also achieved up to 70% more damage protection, as well as 25% better surface reflection. These results could allow longer battery life, and improve the user’s capacity to check their wearable outdoors, according to the company.

Corning started to experiment with glass-based cover for consumer electronics in 2005. However, it wasn’t until 2007 the company released their technology for commercial use.

Back then, Steve Jobs was irritated because the prototype for the first iPhone kept scratching on his pocket.

The famous entrepreneur reportedly asked Corning to come up with a thin, toughened glass cover for the upcoming handset. The manufacturer delivered its first Gorilla Glass component soon after.

How does Gorilla Glass work?

Glass breaks when there are flaws on its surface. After some tension, cracks start to propagate in a chain reaction, causing the material to shatter. Corning created a method to compress glass by using potassium ions to prevent fissures.

Jonathan Pesansky, Business Director of Gorilla Glass, explained the ion-exchange process in a simpler way. He suggested picturing a triangular billiards rack holding 15 pool balls. These objects would be close together, yet, there’s enough space for them to roll within the rack.

However, if a person replaces the pool balls with larger tennis balls -the ions- the rack would be too tight to allow any movement.

Samsung’s Gear S3 is the first product to use GLW SR+

The Gorilla Glass SR+ will be based on this process to enable wearable protection, as this type of devices is more propense to get scratches due to heavy daily activity.

On Wednesday, Samsung announced the upcoming Gear S3 smartwatch would be the first gadget to feature Corning’s new glass cover. The wearable is expected to arrive this fall.

Source: Corning