Engineering company MakerBot released their 6th generation of 3D printers. The biggest event is the “Replicator+” and the “Replicator Mini+,” but the company also unveiled the new MakerBot Print mobile app and more.

Their new solutions can go to professionals and educators and print bigger objects in lesser time. The company believes its products offer engineers and designers a more efficient way to turn ideas into 3D models and gives educators a better way to integrate 3D printing into the classroom to teach problem solving and creativity.

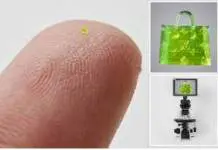

Both Replicator+ and Replicator Mini+ were re-engineered and tested to improve performance and make them faster and easier to use. For businesses, Replicator+ can print objects as big as 11.6 x 7.6 x 6.5 inches, around 25 percent larger than the earlier model.

Replicator Mini+ is a simpler version of the professional model. However, MakerBot is also launching Thingiverse Education, a website where educators can discover 3D printing classroom content made by other colleagues.

MakerBot also released a new print material to produce high-impact strength prototypes and fixtures, the MakerBot Slate Gray Tough PLA Filament Bundle, a sturdier version of the Tough PLA. The company is offering the Replicator+ at $1,999 and the Mini+ at $999 until October 31.

MakerBot software allows Windows to import 3D designs from SolidWorks directly

The MakerBot Print aims to smooth up the design workflow of 3D models. That’s why the new version of MakerBot Mobile includes a setup feature that walks users through the sync process between a Windows desktop and a MakerBot printer

Once a user links the devices, the new MakerBot Print software will connect any workflow with the computer. What’s more, the printer comes with native CAD support, so it doesn’t need STL files.

The app gets rid of the need to convert CAD formats to the company’s native format, and also removes the print preparation step. It’ll also manage to print from a single computer to multiple devices in queue jobs.

The software supports over 20 CAD formats at the same time, so users can go from authoring to prepping and printing while skipping the conversion process.

With the software, users can organize 3D files into multiple projects and email them as attachments to collaborate with others. Storing the information as complete project files rather than stand-alone model data allows a user to save the print settings and build several layouts as a single file.

Source: Engadget