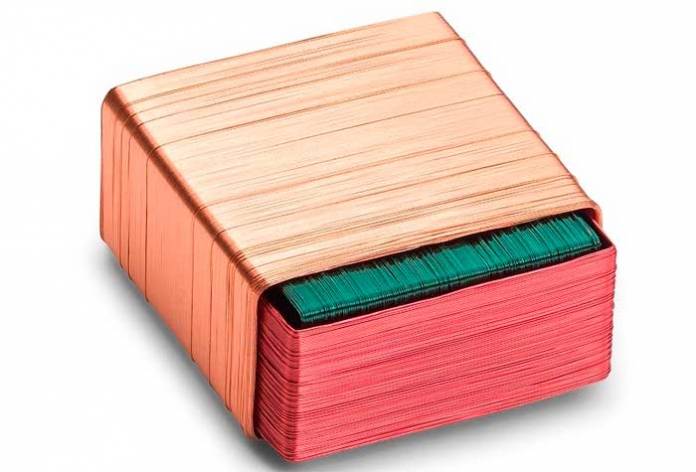

Coil winding is a process for producing electromagnetic coils. The process entails winding an electrical conductor such as a wire in three basic shapes. The shapes can either be a helix, a coil; or spiral depending on the use of the electromagnetic coil. Therefore, the shape and dimensions of the coil are subject to its intended purpose, while characteristics like its degree of inductance, the strength and resistance of the desired magnetic field, determinable by the design of coil winding.

The technology in various industries has created a need for electric currents to interact with magnetic fields. Electromagnetic coils are significant in facilitating such a link between electric currents and magnetic fields. This kind of technology has enhanced development in different fields, such as the study of earth strata movement based upon sensors placed underground that relay information vital to such a study.

Methods and Machinery Used for Winding

Coil winding is an activity required in mass, given the demand for coils in different industries. The venture is impossible by hand and, therefore, requires the use of automated machinery to achieve precision and volume given the demand for electromagnetic coils from the various industries.

Categorization of the wire winding activity into several groups depends on the type and geometry of the coil. For instance, the wild or jumble, helical, and orthocyclic methods of winding electromagnetic coil are integral to the specific user function. However, wild and jumble methods of winding wire are very inefficient and deployed for users, not in serious industries.

The helical method is more efficient, and it creates layers and switches directions by moving forward and backward. Stakeholders in the industry base the helical method’s drawback on its capability of forming a few layers. This is because when it reaches a certain number of layers, its structure becomes too tight to maintain and is clear in finer wires.

The orthocyclic method is the most efficient and most likely for serious industries to utilize. It is the most optimal for winding coils because the wire in the upper level places well in the grooves created by the space between two wires in the lower layer. You need to understand that wires’ creation is cylindrical and when placed side by side; they form a groove in between. A groove is a space in which another wire of the same diameter places fittingly, therefore utilizing space. The space utilization through minimizing material and space required to facilitate good heat conduction and even distribution of electromagnetic field strength. The attribute is paramount for efficient electromagnetic coils.

Advances in the Electromagnetic Coil Industry

One of the major progress in the industry is the size where the demand for smaller coils is the norm. The phenomenon has pushed the industry to begin making smaller electromagnetic coils made possible by micro coil winding techniques. The miniature coils have made technological advancements in important industries like the manufacture of miniature sensors for the health and environmental sectors.